Underground Storage Tank in Chennai have a wide collection of purposes. Here are the 5 most remarkable objective of Underground Tank Manufacturers in Chennai.

Underground Diesel Storage Tank Manufacturers in Chennai are employ to store water in regions with a low well-water limit or regions where groundwater standard is poor.

Heavy rainwater overflow is the fundamental driver of soil disintegration. Underground HSD Tank Manufacturers in Chennai can be make use of the store water or control water transferral and, thus, prevent soil erosion.

Fire concealment systems must've bring about ingress to water. Commercial properties like manufacturing amenity and warehouses establish water tanks for emergency use. The purpose is to intensify their fire sprinkler systems in the event of a fire hazard.

Grey water contains minor degradation however is valuable for non-drinking purposes. Underground Water Storage Tank Manufacturers in Chennai pipe Line Fabrication in Chennai can be employ to store grey water.

Independent of the environment, ranchers, and farmers generally need acceptance to water. Underground Petroleum Storage Tank Manufacturers in Chennai give water to flooding crops in every single weather sample.

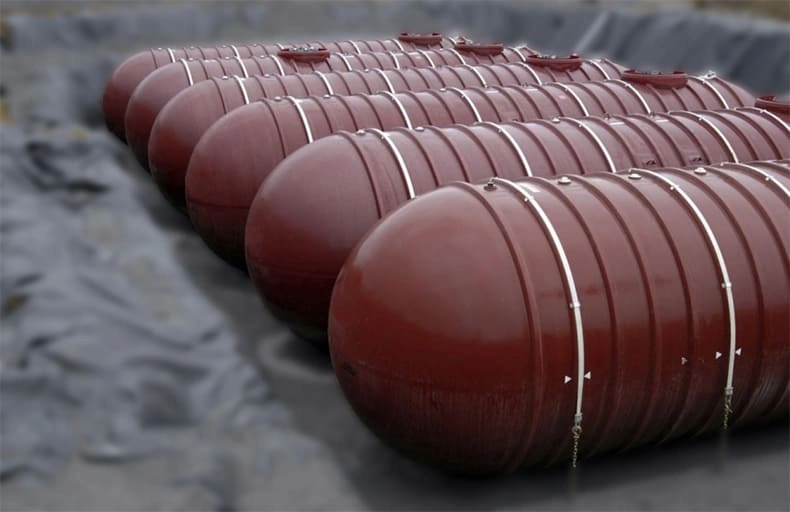

Underground Fuel Storage Tank Manufacturers in Chennai is a single tank or system of tanks that are correlated employ underground piping. Best Underground Storage Tank Company in Chennai must have no less than 10% of their thorough volume underground. Underground Storage Tank Suppliers in Chennai are employ to store various chemical materials , inclusive of petrol and other unsafe chemical substances. You will likewise find others that are utilized for residential facility cause. An Underground Tank Suppliers in Chennai Suppliers Chennai require three sections: the FRP Underground Storage Tank Manufacturers in Chennai, an underground network of pipes, and underground ancillary resources.

There are four necessary types of Underground Oil Storage Tank Manufacturers in Chennai. These include steel or aluminum tanks. Such Underground HSD Storage Tank Manufacturers in Chennai are made utilizing either steel or aluminum. Each Underground Diesel Storage Tank Manufacturers in Chennai must to authorized to the 20KL Underground Tank Manufacturers in Chennai Organization. Aside from that, you can likewise have complex overwrapped Underground Storage Tank Construction in Chennai. These are likewise made employ aluminum/steel, however they incorporate a plastic or carbon compound folded over the metal chamber.

The third type of Double Wall Underground Tank Manufacturers in Chennai is a composite tank enfold with metal liners. Horizontal Underground Tank Manufacturers in Chennai are made utilizing combined material, carbon fiber, or fiberglass, and they highlight a metal liner. In conclusion, you will track down Vertical Underground Tank Manufacturers in Chennai with carbon filaments as tank liners for water systems. These are Underground Chemical Tank Manufacturers in Chennai that are secure with polymer.

Underground Acid Tank Manufacturers in Chennai used to accumulate liquids for later treatment, protection, and usage is called an Underground Tank Manufacturers in Chennai. Petroleum and insecure chemicals are generally stored in Underground HSD Tank Manufacturers in Chennai.

A Underground Diesel Tank Manufacturers in Chennai is a single tank or a group of tanks secured by underground piping. A least of 10% of the total volume of the Underground Tank Fabricators in Chennai must be underground. Petroleum and other definitely unpredictable chemicals are stored in Underground Tank Fabrication in Chennai. May find to employ for residential storage. An Underground Tank Manufacturers in Chennai is made up of three components: the tanks, an underground group of pipes, and underground secondary equipment.

Underground Diesel Tank in Chennai come in four main categories. Underground Petroleum Tank in Chennai made of steel or aluminium falls within this type. FRP Underground Tank in Chennai from either steel or aluminium. The Steel Tank Institute standards should be followed by every tank. In addition, composite covering tanks are an option. These are also formed of aluminium or steel, but the metal cylinder is covered in plastic or a carbon-based material.

A Underground HSD Tank in Chennai that is lined with metal is the third kind of tank. Fiberglass Underground Tank in Chennai have a metal liner and are made of composite, carbon fibre, or fibreglass material. Finally, 20 KL Underground Tank in Chennai are used as tank liners for water systems. These are polymer-lined carbon fibre tanks.

Different tank designs are suited to various purposes and environmental conditions. At least 10% of the liquid in the majority of HSD Tank Manufacturers in Chennai is subsurface. If HSD Storage Tank Manufacturers in Chennai are supported by concrete slabs, they are unprotected to pitting and crack corrosion.

To regulate the use of HSD Storage Tank Manufacturers in Chennai, the EPA initially developed a series of rules. These rules were implemented in an effort to limit petroleum discharge, which can be very expensive and challenging to clean up. If you want to install your own HSD Tank Suppliers in Chennai, you should also check with your state to determine if there are any additional, more uncompromising regulations, such as those for tank liners for water systems, than those set forth by the federal government...

You should be careful of the following information regarding HSD Tank in Chennai. If you want to install one of these tanks, it's crucial to make sure you are aware of the restrictions around them. If you need help installing an HSD Storage Tank in Chennai or have questions about tank liners for water systems, get in touch with us right now.

There are a few Underground Tank Manufacturers systems that may also container other hazardous materials, but most of them are used to store petroleum products. Underground Storage Tank Manufacturers may be problematic for a few important reasons. The first is that many of them were initially constructed using questionable materials or methods, which increases the possibility that they will disintegrate and leak over time. This may cause whatever was being held in the tank to contaminate the soil and groundwater. Another issue is the inability to install anything on top of subsurface tanks if the contents are unknown. This is where Environmental Works comes in.

A Horizontal Storage Tank Fabrication is a essential part of any home or business that depends on a standard inventory of water. Without an appropriately working Underground Tank Manufacturers in Chennai, the water supply could be upset, causing major bother and possibly expensive repairs.

With regards to food storage, there are many features to consider to guarantee that your remain fresh and usable as far as might be possible. One significant component of this is understanding the motivation behind a Underground Diesel Tank in Chennai.

With regards to putting away synthetic chemicals, there are a great deal of advantages that accompany it. There are a wide range of types of Underground Petroleum Tank in Chennai that you can use for this purpose, and every one has its own arrangement of benefits.

A FRP Underground Tank in Chennai holds clean from your reverse osmosis system until an interest for is started in the house or business. Pumped into the tank from the source, similar to a well or a reverse osmosis system. The tank collects until it is full. At the point when you really want admittance to , be it to top your glass off with completely clear water, run a shower, or flood a field, the Underground HSD Tank in Chennai gives you quick access to water.

Fiberglass Underground Tank in Chennai are by and large either pressure tanks or atmospheric tanks. Mark of-use applications, similar to 20 KL Underground Tank in Chennai, as a rule execute pressure tanks. Outside applications or large scope civil storage tasks as a rule utilize atmospheric tanks.

HSD Tank Manufacturers in Chennai are raised to help them in producing water pressure. Assuming a HSD Storage Tank Manufacturers in Chennai is raised sufficiently high, gravity alone can set off water pressure identical from that of large water sponsor pumps. For example, local area water towers follow up on this rule. Water is pumped up into the water pinnacle and afterward held until request is started.

You'll have to ensure the HSD Storage Tank Manufacturers in Chennai is associated with the water line racing to the well. The well pump ought to pumping water directly into the tank. Introduce fittings to course the pipes from the well directly to the HSD Tank Suppliers in Chennai. Install a pressure help valve. Pressure relief valves are designed to open when a predefined pressure is reached and allow water to course through until the strain drops to the ideal level. These prevent excessive pressure develop that could cause the HSD Tank in Chennai to surpass their design limits

HSD Storage Tank in Chennai containing natural fluids, non natural fluids, fumes and can be found in numerous enterprises. Underground Tank Manufacturers can have various sizes, going from 2 to 60 m width or more. They are for the most part introduced inside control bowls to contain spills if there should be an occurrence of burst of the tank. Ventures where Underground Storage Tank Manufacturers can be found are. Petrol delivering and refining, petrochemical and compound manufacturing, bulk storage and move tasks, different businesses drinking or creating fluids and fumes.

A Containment bowl of an item ought to be worked around the Horizontal Storage Tank Fabrication are made of block or concrete and the covering ought to be impenetrable to fluid put away to forestall spills that can cause fire, property harm or pollute the climate.

Of right now utilized tank plans, the fixed-rooftop tank is the most economical to build and is by and large viewed as the base OK hardware for putting away fluids. A normal fixed-rooftop tank comprises of a round and hollow steel shell with a cone-or vault formed rooftop that is for all time fastened to the Underground Tank Manufacturers in Chennai shell.

A commonplace outside drifting rooftop tank comprises of an open-beat round and hollow steel shell furnished with a rooftop that floats on the outer layer of the put away fluid, rising and falling with the fluid level. The drifting rooftop is involved a deck, fittings, and edge seal framework. Drifting rooftop decks are developed of welded steel plates and are of three general sorts dish, boat, and twofold deck. Albeit various dish type decks are right now being used, the current pattern is toward boat and twofold deck type drifting rooftops.

That tank has both, a super durable fixed rooftop and a drifting rooftop inside. There are two essential sorts of interior drifting rooftop tanks. Tanks in which the proper rooftop is upheld by vertical sections inside the tank. Tanks with a self supporting fixed rooftop and no inner help segments

The proper rooftop isn't really liberated from openings however ranges the whole open arrangement region of the vessel. Fixed rooftop tanks that have been retrofitted to utilize an inside drifting rooftop are commonly of the primary sort, while outer drifting rooftop tanks that have been changed over to an inner drifting rooftop tank normally have a self-supporting rooftop.

A Underground HSD Storage Tank Manufacturers is essentially a container that stores liquid fuel, like fuel or petroleum. HSD Storage Tank Manufacturers are regularly utilized where there are high requests for fuel, like industrial sites, or in far off where supply is restricted or excessively far away, for example, homesteads or street work sites.

Contamination in Underground Storage Tank Suppliers is to a great extent brought about by oil eating microorganisms. Since these microbes need water to grow, the service span on cleaning the Underground Storage Tank Dealers varies with humidity, water contamination at the pump and water infiltration into the actual tanks. The typical help span is close to five years for most applications, adapted to conditions in marine or high-humidity regions. Appropriately treating your HSD Storage Tank Manufacturer with a biocide agent can broaden this span fairly, and systems furnished with polishers have been known to dispose of the requirement for Underground HSD Storage Tank Pipeline Fabrication cleaning completely. Underground HSD Storage Tank Company can be cleaned set up with utilization of a biocide specialist and a cleaning apparatus, and they can likewise be cleaned precisely utilizing a scouring medium to remove stuck-on contaminants in the tank.

The plan of a Underground HSD Storage Tank Companies regularly requires checking the strength and stability of the Underground HSD Storage Tank Suppliers construction to endure the heap applied from the put away fuel. The Underground HSD Storage Tank Dealers is additionally designed to endure seismic and wind loading. These estimations and examinations are finished as per applicable norms and codes of practices.

On the off chance that you're as of now bulk buying fuel yet don't have a Underground HSD Storage Tank Manufacturers then you are reasonable encircled by fuel barrels which are unattractive and take up a lot of room. That as well as they are absolutely not the most productive or most secure technique for fuel storage.

Effectively top off equipment on-site: The fundamental explanation companies buy HSD Storage Tank Manufacturers is for on location fuel access nonstop, consistently. Along these lines, machines can run relentless without stopping for fuel tops off on the grounds that the Underground Storage Tank Suppliers is associated with the fuel supply of the industrial facility machinery. Have access to backup fuel: With a Underground Storage Tank Dealers, you have backup fuel close by for at whatever point a machine or vehicle runs empty.

In the event that you are on the lookout for a HSD Storage Tank Manufacturer, consider the size and space of your office and the filling needs of the processes within reach. Pose yourself the following questions:

Probably the main important points with a Horizontal Storage Tank Manufacturers are its size and limit and how those elements correspond to the requirements of your facility. All that matters is how much fuel your operations require.

The fuel type utilized in your tasks will determine your requirements in a Underground HSD Storage Tank Pipeline Fabrication plan. In the event that you intend to utilize combustible fluids, you should have a Underground HSD Storage Tank Company that is twofold walled or put away in a tub or dike. In the event that you intend to utilize more than one kind of liquid, you will require a different Underground HSD Storage Tank Companies for each.

Storage spaces assume a vital part in the unrefined crude oil products industry. They act as a strategic midstream link between the upstream (exploration and production) and the downstream (refining) fragments of the oil industry.

Furthermore, they support refining organizations by putting away finished results. Storage terminals are not just used to store essential, moderate and final results; they work with the constant stock of feedstock to treatment facilities and chemical plants in the processing business and retain vacillations in sales volumes. Each adjustment of the method of transport requires storage capacity limits (terminals with tank storage spaces). A proficient oil industry planned operations chain would be incomprehensible without such framework.

The oil storage area is portrayed by economical growth, with the plan of action guaranteeing repeating income and high ebitda edges. Because of the restricted direct openness to product costs (outsider storage suppliers don't possess the oil they store), the oil storage area is undeniably less recurrent than the energy business. Accordingly, this resource class is appealing for foundation centred financial backers.

Storage additionally offers income creating auxiliary services. The inflows might shift relying upon the interest for such services. These incorporate throughput services, mixing, heating and between tank moves.

Many significant energy companies and brokers own and work terminal storage to assist with coordinating their upstream or downstream resources into the commercial centres. Albeit the fundamental abilities of such terminals are in many cases equivalent to the ones possessed by free administrators, overall they don't give storage to outsiders.

Notwithstanding, by using outsider storage suppliers, significant energy companies can keep away from the enormous capital consumption expected to build their own foundation. Free storage suppliers have greater adaptability and can change better to advertise developments in light of the fact that their storage is available to the open market and is utilized by outsiders.

The primary interest driver for the tank storage industry is the improvement of the transport volume of endlessly oil products. Not entirely settled by complete utilization and additionally the handling volume of rough endlessly oil items and by profession streams.

The area of terminal resources is likewise a huge worth driver: the center terminals are strategically set up and are less delicate to neighbourhood and territorial financial conditions as their business action is connected with worldwide exchange (hence less unpredictable and with a lower risk profile).

Storage capacity increments are driven by market structure (contango versus backwardation) and don't show areas of strength for a with spot oil costs. Presently, there are a few limit extension projects arranged/continuous in the principal exchanging center points (recorded previously). As per Insights Global, all out tank capacity limit might increment by c 10% in the following couple of years (from c 1bn cubic meters of capacity limit in 2020).

There is a gamble of declining interest for street fills because of environment strategy, further developed motor effectiveness and the reception of electric vehicles. Be that as it may, we would expect expanded interest for the mixing of biofuels, thus the requirement for tank capacity (where a large part of the mixing happens). Notwithstanding, in case of lower nearby interest, European treatment facilities could build their volume of products, which would increase interest for storage.

As indicated by the International Energy Agency, worldwide oil request is as yet developing; by 2025 worldwide oil utilization ought to reach 103.2mb/d (an increment of 3.5mb/d from 2019 levels). In any case, in its Sustainable Development Scenario (steady with worldwide net-zero emanations by 2070) oil request declines by 3mb/d over a similar period. A pathway to net-zero discharges internationally by 2050 would require much more keen falls.

A contango happens when prospects costs are higher than current spot costs. In the event that the spread between the costs is sufficiently enormous to cover capacity, money and transportation costs, dealers can create a gain by purchasing oil now and selling it on the prospects market for conveyance later. Be that as it may, to exploit this benefit, dealers need storage (and transport) limit. In this situation, storage rates regularly will generally increase, yet the charges from subordinate services might fall because of lower use of these services.

Backwardation happens when prospects costs are lower than current spot costs. Storage rates will generally fall during backwardation however is adjusted by higher subordinate expenses since use of auxiliary services commonly rises.

FRP tanks are constructed from a composite of fiberglass and resin. The fiberglass imparts strength, while the resin serves as a binding agent for the fibers. Together, they create a lightweight and highly corrosion-resistant material known as FRP (fiber-reinforced plastic). The term FRP Tank Manufacturers encompasses a variety of composites, including glass-reinforced plastic (GRP) and fiber-reinforced polymer (FRP).

FRP tanks are engineered to store various materials, including water, chemicals, and hazardous waste. They are available in cylindrical, rectangular, and square shapes and sizes for convenience, and FRP Tank Suppliers can also customize them to fulfill specific requirements, such as the installation of baffles or particular coating applications.

FRP Tank Dealers offer numerous advantages over traditional steel tanks.

FRP Tank Fabrication Companies are designed to withstand exposure to corrosive substances and conditions, exhibiting high levels of corrosion resistance. Consequently, they are ideal for industries such as chemical processing or water/wastewater treatment that require exceptional corrosion resistance.

FRP tanks are lightweight, facilitating easier installation and transportation, and requiring fewer support structures than their steel counterparts, ultimately contributing to lower construction costs.

FRP tanks are recognized for their exceptional durability, featuring long service lives that can endure extreme temperatures while resisting impact damage and abrasion. These characteristics make them an excellent choice for industries that demand high durability, such as oil and gas.

FRP Water Tanks can be very cost-effective. While initial costs may exceed those of traditional steel tanks, their lower maintenance requirements and longer service lives result in significant long-term savings that accumulate over the lifespan of an FRP Storage Tank.

FRP (Fiber Reinforced Plastic) tanks exhibit significant variation in their dimensions, configurations, and intended applications. Typically, the wall thickness of FRP Chemical Tanks ranges from 3mm to 25mm (0.12 inches to 1 inch). As the capacity of the tank increases, the wall thickness usually increases as well; however, the precise requirements are influenced by several factors, including the chemical concentration of the stored substance, as well as the temperature, pressure conditions, and potential mechanical stress of each application. Therefore, it is prudent to consult a qualified engineer or manufacturer prior to selecting any FRP Septic Tank option! To achieve optimal results, it is advisable to consult a qualified engineer or manufacturer to determine the appropriate thickness for a specific FRP Sewage Tank application.

The maximum height of an FRP Pressure Tank is contingent upon various factors, including its diameter, wall thickness, and the materials utilized in its construction.

FRP Fuel Tanks can typically be designed with heights reaching up to 30 meters (100 feet); however, this is dependent on their specific application and design requirements.

To ensure the best outcomes when selecting an FRP Cooling Tower Tank height that is appropriate for any given application, it is recommended to seek guidance from an experienced manufacturer of machined components or an engineer specializing in Fiberglass Tank, who can evaluate your unique needs and assist in establishing design parameters that meet those needs.

In both commercial and industrial environments, the storage of chemicals is a common practice. Furthermore, these stored chemicals are frequently utilized, transferred, and processed from one tank or container to another. In this context, Fiber Reinforced Plastic (FRP) has gained significant traction and popularity due to its performance and durability within the industry. Fiberglass Water Tanks have emerged as a preferred solution across various sectors because of their high strength, reliability, and resistance to corrosion. Therefore, let us examine seven advantages of employing Fiberglass Chemical Storage Tanks in industrial applications.

In contrast to conventional chemical storage tanks constructed from concrete or stainless steel, Fiberglass Septic Tanks are notably lightweight yet robust. The incorporation of glass fiber in the tank enhances its strength-to-weight ratio, facilitating easier transportation and installation. This characteristic is particularly beneficial for industries with limited space or those requiring the installation of multiple tanks. Additionally, manufacturers of Fiberglass Underground Tanks have designed them to be lightweight in order to minimize the structural load on the support system.

Fiberglass Fuel Storage Tanks are recognized for their exceptional corrosion resistance. Chemicals often consist of highly reactive substances such as salts, acids, and alkalis, which can damage the tank material. In this regard, Fiberglass Tank Manufacturers excel as they provide industries with the capability to endure harsh chemicals without corroding, degrading, or rusting. This attribute of the tank also ensures its structural integrity, contributing to an extended lifespan for Fiberglass Tank Suppliers, thereby making it a prudent long-term investment.

FRP chemical tanks exhibit remarkable resistance to chemical corrosion; however, they also possess a high degree of resilience against impact damage. The composite material utilized in these tanks effectively absorbs shock and stress, rendering them suitable for environments where physical impacts are likely. In contrast to conventional tanks that may crack or dent, Fiberglass Tank Price demonstrate superior durability.

Manufacturers of FRP chemical tanks recognize their significance as essential tools across various industries, thus they design Fiberglass Storage Tanks to fulfill the diverse requirements of numerous applications. The flexibility of FRP materials allows for customization according to specific needs. Furthermore, the selection of different resin systems can enhance the overall functionality of the Fiberglass Tank for Water Storage, making it exceptionally versatile. Consequently, FRP chemical tanks are capable of storing a broad spectrum of chemicals.

In comparison to metal and concrete alternatives, Fiberglass Reinforced Plastic Tank (FRP Tank)s are characterized by their low-maintenance nature. Fiberglass Tank Installation necessitate fewer repairs over time due to their resistance to UV degradation, corrosion, and impact damage. Unlike traditional materials that require regular treatment, Fiberglass Tank Design are engineered for longevity with minimal upkeep. Additionally, the cleaning and maintenance of an Fiberglass Tank Capacity are more cost-effective and straightforward, thanks to its outstanding features. This remarkable attribute of the Fiberglass Tank Companies guarantees optimal performance throughout its service life.

Unlike in the past, industries are now adopting sustainable practices, and in this transition, Fiberglass Tank Exporters have emerged as a significant option. Furthermore, according to leading manufacturers of Fiberglass Tank Dealers, their production process results in less environmental waste compared to other materials. Due to their high durability, Fiberglass Tank Fabricators do not need frequent replacements, which reduces overall material consumption. Additionally, Fiberglass Tank Construction prevent leaks, protecting the environment from harmful and hazardous chemicals. Therefore, choose FRP Tank Manufacturers if you care about the environment and wish to give back to nature.

Lastly, thermal stability is another advantage of FRP Tank Suppliers. These tanks serve as excellent insulators, allowing them to maintain the temperature of the chemicals stored within. This characteristic is vital in industrial settings, as inadequate temperature control can result in damage and dangerous reactions.

FRP (Fiberglass Reinforced Plastic) tanks are the preferred option for chemical storage in various industries. Here’s why:

Exceptional Durability: FRP Tank Dealers are extremely durable and naturally resistant to corrosion in aggressive chemical environments. This durability ensures the safety of the stored chemicals and prolongs the lifespan of the storage tank, thereby reducing the frequency of replacements.

Safety Features: Safety is paramount in chemical storage. FRP Tank Fabrication Company provide numerous safety benefits, including non-conductive materials, chemical inertness, corrosion resistance, leak prevention, impact resistance, and adherence to quality control standards.

Cost-Effectiveness: While FRP tanks may have a higher initial cost compared to traditional tanks made of steel or concrete, they require minimal maintenance and have a long service life. Essentially, FRP tank offer a strong return on investment. Moreover, their lightweight nature facilitates easier transportation and installation.

Versatility: FRP Water Tanks exhibit remarkable versatility. They can be tailored to meet customer specifications and specific applications. FRP Storage Tanks are available in a variety of shapes and sizes. The selection depends on the chemical storage requirements. FRP Chemical Tank can accommodate acids, alkalis, solvents, and other hazardous materials.

Environmental Sustainability: FRP Septic Tanks are produced using eco-friendly materials, contributing to environmental protection. Unlike traditional materials that may involve harmful chemicals, FRP tanks are naturally resistant to corrosion and do not release harmful substances into the environment.

Regulatory Compliance: FRP Sewage Tanks are engineered to comply with industry standards and regulatory requirements for chemical storage. BS Projects Private Limited, located in Mumbai, India, manufactures FRP products. They ensure that their FRP Pressure Tanks and other products adhere to safety codes and guidelines.

One of the most common applications of FRP Fuel Tank is for water storage. FRP Cooling Tower Tanks are designed to hold potable water, irrigation water, or even rainwater for residential, agricultural, or commercial purposes. Fiberglass Tanks are lightweight and can be manufactured in various configurations and sizes based on user needs. Their non-corrosive properties ensure that the water remains safe for consumption or use without any contamination from the tank material.

In industries where chemicals need to be stored or processed, Fiberglass Water Tanks are the preferred option due to their resistance to corrosion. Fiberglass Chemical Storage Tanks are specifically designed to handle a range of chemicals, including acids, alkalis, and other corrosive substances. Their ability to resist chemical reactions ensures that the stored materials remain uncontaminated, and the Fiberglass Septic Tank themselves remain undamaged.

An Fiberglass Underground Tank serves as an eco-friendly solution for waste management. Fiberglass Fuel Storage Tanks facilitate the decomposition of organic waste into useful by-products, including biogas and water, through the natural process of anaerobic digestion. The lightweight and non-corrosive properties of FRP make it an ideal material for biodigester tanks, as it can withstand the biochemical processes occurring within the tank without deteriorating.

For communities or industries seeking sustainable waste management solutions, Fiberglass Tank Manufacturers provide a durable, low-maintenance option. Fiberglass Tank Suppliers help reduce environmental pollutants by converting waste into biogas, which can be utilized as an energy source.

Like biodigester tanks, Fiberglass Tank Price are engineered to manage and treat wastewater, particularly in areas lacking centralized sewage systems. Fiberglass Storage Tanks retain wastewater and facilitate the separation of solids from liquids, with the liquid component being discharged into a leach field. The use of Fiberglass Tank for Water Storage offers a significant advantage, as the material is resistant to rust and chemical reactions from the waste.

Fiberglass Reinforced Plastic Tank (FRP Tank) is easier to install and transport due to their lightweight design. Their construction reduces the need for frequent maintenance or repairs, a common issue associated with concrete or metal septic tanks. For households, businesses, or industries located in remote or off-grid areas, Fiberglass Tank Installation present a reliable waste management solution.

Fiberglass Tank Design are primarily utilized for the storage of petroleum products, including gasoline, diesel, and aviation fuels. Fiberglass Tank Capacity are resistant to corrosion caused by fuel and are designed to prevent leaks and spills. Their non-conductive properties also enhance safety in environments where static electricity could pose a risk.

Fiberglass Tank Companies are specifically designed to conserve water for firefighting needs. These tanks are constructed to withstand severe environmental conditions, ensuring that the water remains clean and accessible during emergencies. They are especially beneficial in areas where water resources are limited, making a water reserve for firefighting essential.

Fiberglass Reinforced Plastic (FRP) storage tanks are gaining popularity in the market due to their outstanding performance features. Fiberglass Tank Exporters are utilized for various applications, including the storage and transportation of chemicals, fuels, and water. If you are contemplating the purchase of a unit for residential or commercial purposes, continue reading. We will outline five important characteristics of FRP storage tanks that enhance their value for any application.

FRP storage tanks are perfect for holding a range of chemicals and fuels because they do not corrode or deteriorate easily. These units are made from layers of resin and fiberglass, which provide them with high resistance to the effects of chemicals, moisture, and UV radiation. This corrosion resistance also makes Fiberglass Tank Dealers an ideal option for storing corrosive materials.

Fiberglass Tank Fabricators are recognized for their strength and longevity. The multiple layers of resin and fiberglass that comprise this unit protect it from significant damage caused by impact and abrasion. The rotational molding process and the use of specific high-density linear polyethylene guarantee that this unit has excellent impact strength and resistance to chemical agents, temperature fluctuations, harsh weather conditions, and UV rays. Additionally, Fiberglass Tank Construction is opaque, which prevents sunlight from reaching the stored liquid, thereby reducing the growth of algae.

Unlike steel tanks that necessitate heavy machinery and specialized expertise for installation, FRP Tank Manufacturers can be set up effortlessly with standard tools. Moreover, their lightweight design makes them perfect for locations where heavy equipment is impractical.

FRP Tank Suppliers demand minimal maintenance. There is no need for regular painting or coating to guard against corrosion. Furthermore, their smooth surfaces facilitate easy cleaning, which aids in sustaining their performance over time.

When compared to other storage tank alternatives like steel or concrete tanks, FRP Tank Dealers are a cost-effective choice. These units are cheaper to produce and transport, making them a more budget-friendly option for various applications. Additionally, their lightweight characteristic means they require less equipment and labor for installation, further lowering their overall cost.

FRP Tank Fabrication Company suffer from rust, require ongoing maintenance, and deteriorate over time. This escalates maintenance expenses and safety hazards while diminishing their service life.

Industrial FRP tanks address the most significant storage challenges as they are:

Industrial FRP tanks do not rust or corrode like conventional metals. They are constructed from materials that withstand moisture, salt, and harsh chemicals, preventing chemical reactions, minimizing contamination risks, and eliminating the necessity for frequent repairs.

FRP storage tanks are manufactured using the advanced filament winding technique, which enhances strength and durability. They can operate in harsh environments with minimal wear, cracking, or breakdown.

Industrial FRP tanks effectively prevent leaks that could result in contamination, fines, and cleanup efforts. Their seamless and non-corrosive design counters two primary causes of leaks: cracks and rust.

An FRP water storage tank greatly decreases maintenance expenses. There is no requirement for regular inspections, protective coatings, or expensive repairs. This durability further minimizes downtime and ensures operations continue smoothly, saving both time and money for businesses.

Polypropylene Storage Tanks are crucial for industries that manage corrosive or reactive materials. Renowned for their high chemical resistance, Polypropylene Tanks are perfect for storing acids, alkalis, and solvents without the risk of contamination or damage. Their lightweight construction facilitates easier installation and relocation compared to conventional metal tanks. Manufacturing sectors such as pharmaceuticals, chemicals, food processing, and textiles depend significantly on Polypropylene Tanks for safe storage and processing. Additionally, Polypropylene Tanks Manufacturers provide excellent thermal insulation, low moisture absorption, and outstanding crack resistance. Their non-reactive characteristics help preserve product purity, particularly in sensitive industrial applications. Consequently, PP Tank Manufacturers enhance operational efficiency, lower maintenance costs, and improve safety standards in contemporary manufacturing settings.

A PP Storage Tank is a vessel constructed from a thermoplastic polymer that is resistant to chemicals and heat. Polypropylene Storage Tank belong to the larger category of PP Chemical Storage Tanks and are made from materials that are stronger and denser than polyethylene. They are ideal for storing corrosive substances due to their high heat and chemical resistance. Their robust design ensures durability even in challenging industrial conditions. We are a prominent manufacturer of Polypropylene Chemical Tanks utilizing co-polymer and homopolymer polypropylene. These materials resist delamination, cracking, and brittleness caused by exposure to opposing chemicals. Their remarkable strength and insulation capabilities make them suitable for storage for acids, alkalis, and other chemical solutions.

PP Plating Tank also demonstrate outstanding resistance to moisture absorption and temperature changes, which makes them resilient to stress and cracking. With these attributes, they provide dependable and safe storage solutions across various industries.

PP Rectangular Tanks are highly adaptable. Their capacity to adjust to diverse situations renders them favored in numerous industries. Below are some examples of sectors that utilize these thermoplastic marvels:

A prevalent use of PP Cylindrical Tanks is within the pharmaceutical sector. PP Storage Tank Suppliers are crucial for the storage and transportation of sensitive medications and chemicals, owing to their non-reactive properties. While they may not alleviate your cold symptoms, Polypropylene Acid Tanks are certainly working diligently behind the scenes to ensure life-saving drugs remain in optimal condition.

Polypropylene Chemical Storage Tank Manufacturers serve as reliable allies for liquid and chemical storage. Their sturdy construction and corrosion resistance make them ideal for protecting a variety of substances. Whether it’s for storing pool chemicals, fertilizers, or even pickling solutions for gardening enthusiasts, Polypropylene Tank Suppliers manage it all with remarkable ease.

In the textile sector, PP Acid Storage Tanks are employed for mixing, storing, and dyeing different fabrics and textiles. Their resistance to harsh chemicals guarantees the safe handling of dyes and additives, while their smooth surfaces help prevent fabric damage during agitation. Additionally, Polypropylene Tank Fabrication are easy to clean and maintain, which is crucial in an industry where hygiene and precision are paramount.

What do you envision when you think of relaxation? For many, it’s a spa retreat, enjoying a day in a warm and bubbly hot tub. Surprisingly, Polypropylene Storage Tank Manufacturers are integral to making those hot tub experiences possible. Polypropylene Tank Manufacturers In India form the foundation of spa equipment, enabling the heating and distribution of water for relaxing whirlpool baths.

PP Tank Suppliers are not just for land-based uses. These adaptable containers play a crucial role in aquatic environments as well. From aquaculture to aquariums, the non-reactive properties of PP Tanks guarantee the health of aquatic organisms. The next time you admire the vivid hues of fish or the tranquility of underwater scenes, keep in mind that PP Tank Manufacturers are diligently working to foster an environment where aquatic marvels can flourish.

Farms are vital for our food supply, and PP Tank Manufacturer is a key component of contemporary agricultural practices. They aid in the storage and distribution of fertilizers, pesticides, and even irrigation water. Whether it’s a small family-run farm or a large agribusiness, PP Tank Supplier ensure that crops prosper and yields are abundant.

Pressure vessels can pose significant challenges, but PP Tank Suppliers manage the pressure with ease. Their robust construction and capacity to endure high-pressure conditions have secured their place in various sectors, including pneumatic systems, compressed air storage, and hydraulic applications. While others may falter under pressure, PP Tank Exporter remain resilient and reliable.

In the realm of metal finishing, PP Tank Exporters are widely utilized in the galvanizing process to shield metal items from rust and corrosion. With their capability to withstand the most aggressive chemicals, PP Storage Tank ensure that everything from garden fences to automotive components remains durable and visually appealing.

Access to clean water is invaluable, and PP Storage Tanks play a vital role in ensuring its availability. PP Water Tanks are essential in water treatment facilities, where they eliminate impurities and contaminants from drinking water. They manage processes ranging from sedimentation to chemical treatments, ensuring that your glass of water is as refreshing as possible.

PP Water Tanks may not be the first option that springs to mind when considering industrial solutions, yet the adaptable uses and reliable characteristics of PP Chemical Tank warrant some attention. PP Chemical Tanks demonstrate that practicality does not have to compromise efficiency.

Should you require PP Acid Tank for chemical storage, agricultural purposes, or any other application, we are here to assist you. At Miller Plastic Products, we manufacture high-quality, robust PP Acid Storage Tanks that are equipped to handle any challenge, regardless of its difficulty. We can custom-design and weld PP Storage Tank Manufacturer according to your precise requirements. Explore our PP Storage Tank Suppliers gallery today to discover more about the options available, or reach out to us to discuss incorporating these industrious storage solutions into your facility.