Pressure vessels, for private or industrial uses, use exclusive forms of metallic, mainly stainless-steel, which can be welded together so as to manufacture cylinders or spheres. They are designed to comprise drinks and gases at excessive-stress values. Stainless steel strain vessels are becoming more and more popular across the globe owing to the many blessings that they bring about. These benefits may additionally follow on your situation. Using stainless-steel manufactured pressure vessels will increase the chances of success.

Stainless steel pressure vessels can withstand to their meant loading without failing because of deformation, fracture, or fatigue. This structural integrity is given through two very crucial elements: high electricity and high durability. You see, stainless steel is more proof against corrosion in preference to normal metallic. When it’s subjected to air, metallic reacts with oxygen to form rust.

Even if stainless steel is a sturdy material, it can be made to the favoured shape. The welding process, to prevent thermal cracking, impurity elements are eliminated from the steel. Experienced producers take precautions to keep away from leakage by means of trying out every product that comes out of the production line. Additional checking out may encompass a penetrate examination.

Stainless metal is capable of retaining its homes over time, specifically at low-temperature ranges. Pressure vessels manufactured the use of this material are highly within your budget. With right preservation and dealing with, they can final for a very long time and experience price-performance. The extended life span spares the owners the value of obtaining new pressure vessels on a ordinary foundation. An ever-growing range of manufacturers are selecting to build chrome steel tanks over carbon metal tanks due to the fact they require little to no upkeep and there’s no want for extensive refurbishment.

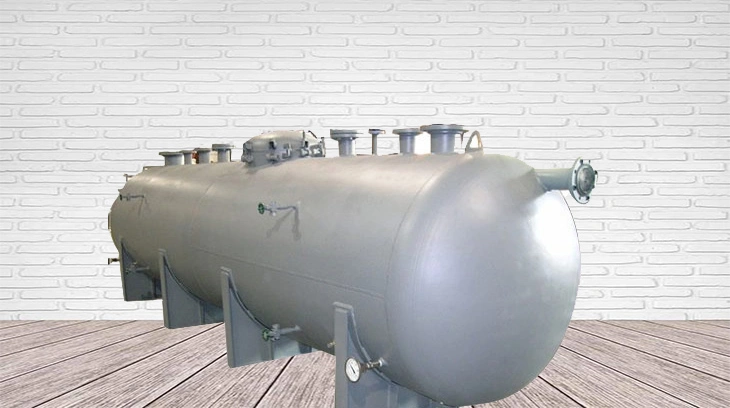

Stainless steel pressure vessels are commonly used inside the chemical, gas, and oil industries. They are locating for compressed air receivers, recompression chambers, distillation towers, autoclaves, and diving cylinders. High call for stress vessels ends in a high turnaround time for production, therefore driving market growth. Although composite substances are gaining in popularity, steel remains the famous person cloth. There are three common types of stainless steel pressure vessels, each serving a special purpose but making a great contribution in terms of production.

Storage vessels, which range from low-performance tanks to high-performance packing containers, are used for the build-up of oil, drinks, and produced water. They are cylindrical in shape and function a floating or fixed roof.

Heat exchangers have facilitated modern processing and production, which we’re all grateful for. The systems paintings by shifting heat among 2 or extra fluids. They are normally separated with the aid of a wall to save you blending. Heat may be unfavourable, that's why it needs to be reused or eliminated to dispose of this troubling concern.

Process vessels are designed for blending, separation, cooling, purification, and changing a cloth’s state. They can be related to other approaches horizontally or vertically. These pressure vessels can face up to high temperature and pressure, meaning that they’re immensely useful.