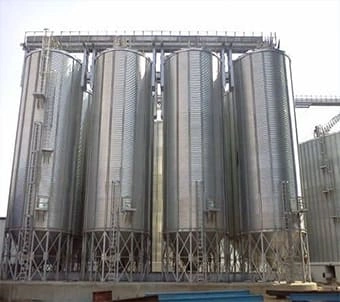

Grain steel silo is also called grain bin, grain storage steel silo. Grain storage silo is utilized to store grains, like rice, wheat, corn and other grain material. Generally, there is different material to build a silo; we can track down wood silo, plastic silo, concrete silo, steel warehouse silo.

We offers a wide range of inspired steel silos for grain storage, giving total storage and installation equipment solution for agricultural industry category everywhere. Following quite a while of storage design and manufacturing experience, grain storage silo offers commercial users the best build in esteem over the existing of the product.

To meet the requirement of grain storage, steel grain silo sufficiently controls the temperature and humidity inside the silo, which prevents grain transform effectively. Certain people assemble concrete silo to store grains, however, concrete silo is 6-10 times the heaviness of steel grain silo. To store a similar volume of grain, steel grain silo's finance is only the portion of that of the concrete silo.

Lift your grain the principal higher than ever with a total grain silo system. We offer the highest grain silos and have the complete biggest grain-holding limits available. More talented and easy to use highlights are added to the grain silos to help you maintain with and protected your important stored grains.

Spiral steel silos have wonderful product durability and top quality execution. Moreover, logical plan and ventilation equipment warranty the quality and safety of the grain. Steel silo vents are installed on the highest point of the silo for heat dispersion and ventilation, which can keep the grain from being frame.

Consider the volume of material your application handles and ensure the silo can be worked to the particular aspects you really want. Dry bulk storage silos are regularly made of shop- cemented steel, field-blasted steel, or cement. (Field-welded steel silos are additionally accessible but are generally usually utilized for liquid applications.)

Consider the silo’s release level carefully, as this is a charge driver. For example, on the off chance that the silo will be utilized for loading trucks, you might require a loading spout (either dustless or not) and conceivably a fettler. Scatter load out requires the option of a necessary residue authority, which can amount to 3 feet to the warehouse's release level. A conditioner can add 2 to 3 additional feet depending upon the unit, but this option will speed up and decrease operation costs.

The size of the area where the silo will be found will help with deciding the silo type and construction technique. Your installation approach will also shift dependent upon whether the silo area is a new construction or a adding to a current facility.

Flyash silos utilizes the most advanced technology and is made of high-quality steel loops. It can meet the requirements of safe storage and economic utilization of fly ash. Flyash silos are intended to meet the client's requirements for execution, design and convenience. Likewise, fly debris storehouses can without much of a stretch pass on and measure fly debris.

It accompanies appropriate inner covering backing to give the most solid tanks. The benefits of fly debris steel storehouses provided by Flyer:

Expertise

in offering right silo for right material storage and transfer needs.

Providing silo with complete underlying scaffolding steel and access stages.

Expertly designed with the most minimal expense.

Meeting clients' necessities for extraordinary execution and advantageous primary availability.

The cement silo is a integral piece of equipment for any substantial creation activity. The silo permits the product to be purchased and stored in bulk, keeping costs to a minimum.

We will help you with assessing your specific requirements to guarantee that the cement silo most appropriate for you is chosen. Factors for silo choice incorporate loading site design, tallness limitations, accessible force source, and the need to move the silo to a substitute area.

A cement silo is the on location storage container that takes into account the capacity and circulation of various concrete blends. cement silo can arrive in a scope of sizes to fit the necessities of building locales. A silo could be an extremely durable construction holding many huge loads of concrete or a compact model to be migrated to various work destinations.

They are typically equipped with some sort of blower to remove the dry concrete into a truck or mixers.Large silo are bound to be found at substantial plants as long-lasting constructions , where completed item is put away until transportation. Notwithstanding, more modest compact silo are ideal everywhere building locales where they can be moved to any place work is being finished. By volume, cement is the most-utilized material on the planet.

We offer a wide scope of storage silos and tanks produced using various sorts of stainless steel. We utilize stainless steel 304 (L) and 316 (L), duplex, very duplex, depending altogether upon the client's needs.

stainless steel is an exceptionally solid and support cordial material. Cleaning the silos is well conceivable with this material and it is profoundly impervious to different climate conditions and mechanical harm.

Stainless steel is famous in the dairy business generally because of its corrosion resistant properties. It contains chromium which fosters a defensive oxide covering on the outside of the metal.

This layer can get harmed if not kept up with appropriately. One of the manners in which the defensive oxide layer of stainless steel can get harmed is by coming into contact with customary carbon steel.

Silos are made of sheet metal, with an aroused covering. Also, in spite of the fact that it might appear to be something else, the expansion in temperature of the sheet because of the warmth of the sun is exceptionally shallow and doesn't influence the grain mass.

The temperature variety that influences the grain mass is brought about by the aging cycles, that is when there is a dampness center that starts to disintegrate the grain, and one of the outcomes is the temperature increase.

Consequently the significance of identifying moisture sources utilizing devices permits one to quantify the temperature inside the silos and set an alert when there is an increment in temperature in any of the focuses, showing that something significant is occurring inside.

When the dampness has been recognized, it is important to act, either by ventilating, in other words, putting air at medium pressing factor inside the silos ; or by recycling and moving the grain to somewhere else, which is a lot more secure.

Our Industrial silos are specially crafted and designed for the storage of dry bulk products like cement, plastics, flour, sugar, tars, slag, fly debris, and lime, and liquid products like water, liquid compost and molasses.

All Industrial silos are specially crafted and come in sizes going from three feet in width to more than 14 feet in distance across

Manufactured from gentle or stainless steel

Avoided with single or twofold entryway access

I-Beam leg support

Base ring for uniform mounting on structure

Stub legs for mounting on pass through structure

Single

and twofold divider split silos

Focus, side or offset draw cones with your decision of release size (flanged)

Level base

Tightened (more modest measurement at top, bigger width at base)

Flare-stacks

Concrete silos offer the ideal answer for the costly and time-consuming for adding concrete to the substantial blend. A concrete silos empowers our clients to purchase their concrete powder in mass, store it and apportion when required.

This keeps our clients as adaptable as could be expected, as they aren't depending on conveyances or sitting tight for concrete packs to be painstakingly loaded and unloaded.

Our steel concrete silos are ideally suited for the capacity of concrete or PFA making it simpler than any time in recent memory to blend tremendous amounts of cement, mortar or grout in a short measure of time because of their ability of as much as 75 tons and drills for exact discharge.

Silos are made of sheet metal, with a stirred covering. Furthermore, in spite of the fact that it might appear to be in any case, the expansion in temperature of the sheet because of the heat of the sun is exceptionally shallow and doesn't influence the grain mass. The temperature variety that influences the grain mass is brought about by the maturation processes, that is when there is a dampness centre that starts to weaken the grain, and one of the outcomes is the temperature increment.

Indeed. It is fundamental to safeguard the grain from stickiness to ensure ideal storage conditions. Along these lines, the silo is provided with clay to seal the joints between the ferrule sheets; and elastic washers are utilized for the screws. In this way, it is suggested that the underpinnings of ground silos be assembled marginally raised starting from the earliest stage.

The temperature inside the silos must be directed to guarantee the grains don't get harmed; that incorporates appropriate air circulation to control how much dampness inside the shut compartment. Another significant thing is to defend the grains from bugs; chemical control inside the silos is expected to shield it from bugs and different rodents. So silos which are bulk storage systems for different kinds of food grains.

Storage silos are structures designed to store grain and other material in mass or powder. They are likewise utilized for storing different components like concrete, calcium oxide, calcium hydroxide, actuated carbon or plastic gums, among others. The most widely recognized storage silos are tube shaped with a metal help in spite of the fact that there are likewise rectangular and square ones. They are like a pinnacle and the material with which they are fabricated can be metal, stainless steel, supported concrete, wood, built up plastic, fiberglass, and so forth.

A silo is a construction for storing mass materials. Silos are utilized in horticulture to store grain or aged feed known as silage. Silos are all the more ordinarily utilized for bulk storage of grain, food items. Silos are involved by different businesses for bulk storage of coal, concrete, sand, woodchips, metal waste, food items and sawdust. Silos range in range from around 10m to 90m with a limit of 20 to 80 tons.