A SS Pressure Vessel manufacturers Chennai is a fixed nook container designed to contain gases or fluids at a pressure higher or lower than the ambient pressure. A few instances of Chemical Pressure Vessel Manufacturers Chennai are glassware, autoclaves, compacted gas chambers, blowers, vacuum chambers and specially crafted lab vessels.

In designing High Pressure Vessel Manufacturers Chennai, engineers consider different variables, for example, the greatest permissible working pressure the equipment will insight, the temperature of the material contained, the type of material used to build, and the kind of burden it will be exposed to.

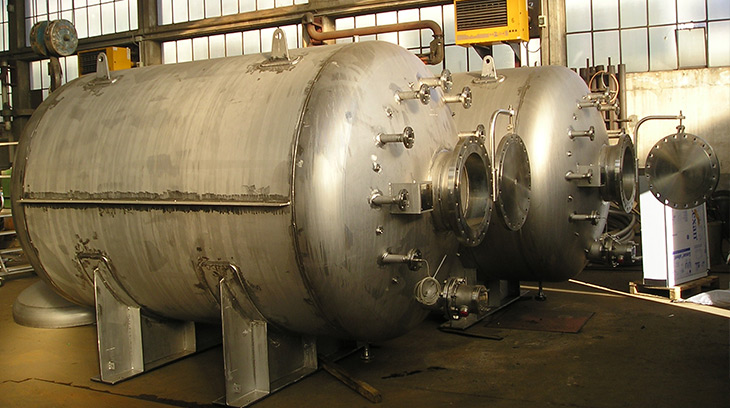

Different shapes and sizes portray Industrial Pressure Vessel Manufacturers Chennai, which range from little cylinders for propane storage to huge tanks in chemical processing plants. Normal shapes incorporate round and hollow, circular, and rectangular. Manufacturers normally make MS Pressure Vessel Manufacturers Chennai from metals like steel, stainless steel, or aluminium; however some additionally utilize composite materials. The pressure the vessel contains decides the thickness of its walls, requiring thicker walls for higher pressures.

Pressure Vessel Equipments in Chennai are particular compartments that hold gases or fluids at higher pressures than the encompassing environment. They are frequently made of strong materials that can endure high pressures to guarantee their uprightness and safety. Because of the dangers related with their utilization, they are exposed to broad guidelines and rules to prevent accidents and maintain proper activities.

A Stainless Steel Pressure Vessel Manufacturers Chennai can hold enormous volumes of substances inside a reduced space. This is profitable in the petrochemical and energy industries, where the storage and transport of materials are fundamental for proficient production processes. Notwithstanding its ability for enormous volume storage, it can maintain the stored substances' honesty and strength over the long haul. This guarantees that the items stay unaltered and prepared for use.

One way the SS Pressure Vessel Manufacturers Chennai adjust to explicit circumstances is through their custom design. The Pressure Vessel Tank Manufacturers Chennai can be built from different materials, including metals and composites. This empowers architects to choose choices the most appropriate to endure the particular circumstances they will experience. These may incorporate exposure to destructive substances, outrageous temperatures, or high-pressure conditions.

Pressure vessel Manufacturers Chennai are constructed observing quality guidelines and rules laid out by associations like the American Culture of Mechanical Architects. These regulations oversee the entire life cycle of the container, from design and material determination to construction, testing, and maintenance. Quality standards consistence is particularly significant in areas where safety is fundamental, like compound handling and power creation.

SS Pressure vessels Manufacturers Chennai can take on different structures, from tube shaped tanks to circular containers and, surprisingly, more complex calculations. This permits specialists to improve the shape to expand space use, whether in an industrial setting or a commercial machine. Furthermore, they can have various introductions, meaning they can be installed above ground, covered underground, or incorporated into existing designs.

SS pressure vessel manufacturers Chennai serves a huge number of capabilities across various industries. It stores gases, liquids, and even solids at high pressures or temperatures. Its applications range from maintaining the pressure in water supply systems to containing reactive chemicals in the petrochemical industry. It can likewise have inherent safety highlights like help valves and emergency venting systems.

One of the upsides of pressure vessels Manufacturers Chennai is their low working expense, credited to their negligible maintenance necessities and high corrosion obstruction. Dissimilar to different containers and storage strategies, which can be adversely impacted by oxygen, these Pressure Vessel Storage Tank Manufacturers Chennai are airtight fixed. They likewise just house the particular material they are designed to store, generally not oxygen.

Coming up next are the top justifications for why clients ought to choose a specially designed pressure vessels to store high pressure gases or liquids.

Organisations situated in various industries use pressure vessels Manufacturers Chennai. These incorporate oil and gas, chemical, and auto industries. Every one of these industries utilizes various kinds of liquids or gases in shifted amounts. This additionally implies that angles like SS Pressure Vessel size and shape, temperature, pressure rating, will be different for every application. For example, the oil and gas industry requires custom High Pressure Vessel Manufacturers Chennai, which can deal with high temperatures, as well as elevated degrees of destructiveness. Thus, the Industrial Pressure Vessel Manufacturers Chennai should be designed with the end goal that they can meet explicit application requirements.

Pressure vessels Suppliers Chennai are produced to meet the guidelines of the ASME BPVC. Contingent upon the industry and application, a few MS Pressure Vessel manufacturers Chennai should be built utilizing explicit manufacturing materials. For example, the medical industry will expect Pressure Vessel Equipment to be produced using stainless steel, as the material meets sterility necessities. The material will likewise should be chosen for different highlights like cost, strength, simplicity of welding, and so on.

Numerous clients get new equipment to improve their services or facility operations. In such circumstances, they require Stainless Steel Pressure Vessel Manufacturers Chennai that can store explicit volumes of gases or fluids. Custom pressure vessels can be designed to guarantee that the amount is adequate for the volume of the gas or liquid to be stored. Likewise, as the SS Pressure Vessel Suppliers Chennai is fabricated to ASME guidelines, it will reinforce confirmation that the vessel will work appropriately with the new equipment.

While choosing a pressure vessel in Chennai, various variables should be considered to guarantee its reasonableness for the expected application. Working circumstances, for example, pressure and temperature are basic contemplations, as they direct the Pressure Vessel Tank Manufacturers Chennai determinations. The material utilized in the vessel's construction should be viable with the substances it will contain to prevent corrosion or contamination.

Moreover, administrative consistence is vital to guarantee that the Pressure Vessel Storage Tank Manufacturers Chennai satisfies every important rule and guidelines for safety and natural protection. Choosing the right pressure vessel in Chennai is urgent for maintaining functional effectiveness and preventing possible perils. Consequently, cautious thought of these variables is fundamental to guarantee that the choose pressure vessel Manufacturers Chennai meets the particular prerequisites of the application and consents to every important guideline.

Pressure vessels in Chennai play a critical role in various industrial processes, serving as containers designed to hold gases or liquids at pressures substantially different from ambient conditions. These vessels are used across a wide range of industries, including petrochemical, pharmaceutical, energy, and manufacturing. The manufacturing of pressure vessels requires precision, adherence to strict regulations, and a commitment to safety. This essay explores the importance of pressure vessel manufacturers Chennai in ensuring the safety and reliability of these crucial components.

Pressure vessels are integral components in industrial settings where the containment of substances under high pressure is necessary. They are employed in processes such as chemical reactions, heat exchange, and storage of compressed gases. The design and construction of pressure vessels Manufacturers Chennai must consider factors like material strength, corrosion resistance, and the ability to withstand varying temperatures and pressures. Manufacturers play a pivotal role in producing vessels that meet these demanding requirements.

The manufacturing of pressure vessels in Chennai is subject to a myriad of international and national standards and regulations. Organizations such as the American Society of Mechanical Engineers (ASME) and the European Pressure Equipment Directive (PED) set forth guidelines to ensure the safety and integrity of pressure vessels. Manufacturers must comply with these standards to guarantee that their products meet the necessary safety criteria. The adherence to regulations involves rigorous testing, inspection, and certification processes.

Pressure vessel manufacturers in Chennai must possess expertise in materials science and engineering to select suitable materials for construction. The choice of materials depends on factors such as the type of substance to be contained, operating conditions, and durability requirements. Moreover, manufacturers need to employ advanced design techniques to ensure that pressure vessels Chennai can withstand the designed operational pressures while minimizing the risk of fatigue, corrosion, and other potential failure modes.

Quality control is paramount in the manufacturing of pressure vessels. Stringent testing procedures, including non-destructive testing methods like ultrasonic and radiographic testing, are employed to identify potential flaws or weaknesses in the vessel's structure. The quality control process ensures that only vessels meeting the specified standards are released for use, reducing the risk of catastrophic failures that could have severe consequences for both personnel and the environment.

Pressure vessel manufacturers Chennai continually strive for innovation to enhance the performance, efficiency, and safety of their products. Advancements in materials, manufacturing processes, and design techniques contribute to the development of more robust and reliable vessels. This commitment to innovation is essential in meeting the evolving needs of industries while maintaining the highest standards of safety and reliability.

Pressure vessel manufacturers in Chennai play a crucial role in ensuring the safety and functionality of these indispensable components in industrial processes. The intricate interplay of materials science, engineering, compliance with standards, and rigorous quality control measures are essential in the fabrication of pressure vessels. As technology advances and industries evolve, manufacturers must remain at the forefront of innovation to meet the increasing demands for safety, efficiency, and sustainability in pressure vessel design and production in Andhra. Ultimately, the collaborative efforts of manufacturers, regulators, and industry stakeholders are essential in fostering a culture of safety and reliability in the realm of pressure vessel Manufacturers Chennai.

Contact Us