A SS Pressure Vessel manufacturers India is a fixed crevice container designed to contain gases or fluids at a pressure higher or lower than the environment pressure. A few instances of Chemical Pressure Vessel Manufacturers India are glassware, autoclaves, compacted gas chambers, blowers, vacuum chambers and specific crafted lab vessels.

In designing High Pressure Vessel Manufacturers India, engineers believe different variables, for example, the greatest permitted working pressure the equipment will discernment, the temperature of the material composed, the type of material used to build, and the kind of significance it will be exposed to.

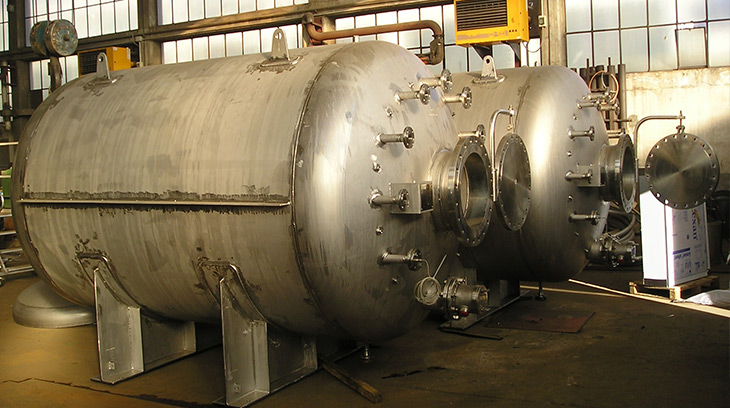

Different shapes and sizes portray Industrial Pressure Vessel Manufacturers India, which range from little cylinders for propane storage to huge tanks in chemical rectifying plants. Normal shapes embody round and hollow, circular, and rectangular. Manufacturers commonly make MS Pressure Vessel Manufacturers India from metals like steel, stainless steel, or aluminum; however some additionally employ composite materials. The pressure the vessel contains concludes the thickness of its walls, essential thicker walls for higher pressures.

Pressure Vessel Equipments in India are appropriate compartments that hold gases or fluids at higher pressures than the encompassing environment. They are frequently made of strong materials that can undergo high pressures to covenant their uprightness and safety. Because of the dangers related with their employment, they are exposed to broad guidelines and rules to avoid accidents and maintain proper activities.

A Stainless Steel Pressure Vessel Manufacturers India can hold immense volumes of element inside a reduced space. This is effective in the petrochemical and energy industries, where the storage and transport of materials are basic for skilled production processes. Notwithstanding its ability for extensive volume storage, it can prolong the stored substances' honesty and strength over the long haul. This covenant that the items stay unimpaired and prepared for use.

One way the SS Pressure Vessel Manufacturers India adjusts to specific circumstances is through their custom design. The Pressure Vessel Tank Manufacturers India can be assembled from different materials, including metals and blend. This empowers architects to choose options the most appropriate to endure the appropriate circumstances they will acquaintance. These may assimilate exposure to harmful substances, disgraceful temperatures, or high-pressure conditions.

Pressure vessel Manufacturers India are constructed detect quality guidelines and rules laid out by corporation like the American Culture of Mechanical Architects. These regulations oversee the continuous life cycle of the container, from design and material assurance to construction, testing, and maintenance. Quality standards consistence is specifically revealing in areas where safety is elementary, like compound handling and power creation.

SS Pressure vessels Manufacturers India can take on different structures, from tube shaped tanks to oblique containers and, astonishingly, more complex calculations. This allows specialists to enhance the shape to expand space use, whether in an industrial setting or a commercial machine. Furthermore, they can have various prologue, meaning they can be installed above ground, covered underground, or embody into existing designs.

SS pressure vessel manufacturers India serves a huge number of ability across various industries. It stores gases, liquids, and regular solids at high pressures or temperatures. Its applications range from continue the pressure in water supply systems to exhaustive reactive chemicals in the petrochemical industry. It can likewise have inherent safety highlights like help valves and emergency reveal systems.

One of the upsides of pressure vessels Manufacturers India is their low working insurance, credited to their imperceptible maintenance necessities and high corrosion obstruction. Dissimilar to dissimilar containers and storage strategies, which can be unfavorably impacted by oxygen, these Pressure Vessel Storage Tank Manufacturers India are airtight fixed. They furthermore just house the specific material they are designed to store, generally not oxygen.

Coming up next are the top confirmation for why clients need to choose a specially designed pressure vessels to store high pressure gases or liquids.

Organizations situated in numerous industries use pressure vessels Manufacturers India. These incorporate oil and gas, chemical, and auto industries. Every one of these industries employ various kinds of liquids or gases in shifted amounts. This additionally implicit that angles like SS Pressure Vessel size and shape, temperature, pressure rating, will be different for every requisition. For example, the oil and gas industry requires practice High Pressure Vessel Manufacturers India, which can deal with high temperatures, as well as exalted degrees of harmfulness. Thus, the Industrial Pressure Vessel Manufacturers India should be conscious with the end goal that they can meet certain application requirements.

Pressure vessels Suppliers India are performed to meet the guidelines of the ASME BPVC. Contingent upon the industry and application, a few MS Pressure Vessel manufacturers India should be built utilizing definitive manufacturing materials. For example, the medical industry will anticipate Pressure Vessel Equipment to be produced using stainless steel, as the material meets sterility necessary. The material will furthermore should be chosen for different highlights like cost, strength, obviousness of welding, and so on.

Numerous clients get new equipment to develop their services or facility operations. In such circumstances, they obligate Stainless Steel Pressure Vessel Manufacturers India that can store definitive volumes of gases or fluids. Custom pressure vessels can be designed to guarantee that the amount is sufficient for the volume of the gas or liquid to be stored. Likewise, as the SS Pressure Vessel Suppliers India is invent to ASME guidelines, it will reinforce affirmation that the vessel will work suitably with the new equipment.

While choosing a pressure vessel in India, various variables should be designed to guarantee its rationality for the expected application. Working circumstances, for example, pressure and temperature are basic deliberation, as they direct the Pressure Vessel Tank Manufacturers India determinations. The material employ in the vessel's construction should be viable with the substances it will accommodate to prevent corrosion or pollute.

Moreover, administrative stability is vital to guarantee that the Pressure Vessel Storage Tank Manufacturers India satisfies every important rule and guidance for safety and natural protection. Choosing the right pressure vessel in India is urgent for protect functional efficiency and preventing possible perils. Consequently, vigilant thought of these variables is fundamental to assurance that the choose pressure vessel Manufacturers India meets the particular essential of the application and authorized to every important guideline.

Pressure vessels in India play a critical role in numerous industrial processes, serving as containers designed to hold gases or liquids at pressures significantly different from surround conditions. These vessels are used around a wide range of industries, including petrochemical, pharmaceutical, energy, and manufacturing. The manufacturing of pressure vessels requires precision, obedience to strict regulations, and a loyalty to safety. This essay analyze the importance of pressure vessel manufacturers India in provide the safety and reliability of these pivotal components.

Pressure vessels are integral element in industrial settings where the containment of potentiality under high pressure is necessary. They are occupied in processes such as chemical reactions, heat exchange, and storage of compressed gases. The design and construction of pressure vessels Manufacturers India must regard factors like material strength, corrosion resistance, and the capacity to withstand varying temperatures and pressures. Manufacturers play a crucial role in producing vessels that meet these critical requirements.

The manufacturing of pressure vessels in India is essence to a myriad of international and national standards and instructions. Organizations such as the American Society of Mechanical Engineers (ASME) and the European Pressure Equipment Directive (PED) set forth instruction to ensure the safety and uprightness of pressure vessels. Manufacturers must obey with these standards to assurance that their products meet the necessary safety criteria. The conformity to regulations involves accurate testing, inspection, and certification processes.

Pressure vessel manufacturers in India must possess proficiency in materials science and engineering to select appropriate materials for construction. The choice of materials depends on factors such as the type of substance to be inhibited, operating conditions, and persistence requirements. Moreover, manufacturers need to operate advanced design techniques to provide that pressure vessels India can resist the designed operational pressures while diminish the risk of fatigue, corrosion, and other imaginable failure modes.

Quality control is predominant in the manufacturing of pressure vessels. Stringent testing technique, including non-destructive testing methods like ultrasonic and radiographic testing, are operating to identify potential flaws or weaknesses in the vessel's structure. The quality control process safeguard that only vessels meeting the specified standards are released for use, diminish the risk of catastrophic failures that could have severe substance for both personnel and the environment.

Pressure vessel manufacturers India continually strive for alteration to enhance the performance, capability, and safety of their products. Advancements in materials, manufacturing processes, and design methodology contribute to the development of more robust and predictable vessels. This commitment to innovation is crucial in meeting the evolving needs of industries while protect the highest standards of safety and responsibility.

Pressure vessel manufacturers in India play a pivotal role in ensuring the safety and performance of these indispensable ingredient in industrial processes. The complicated interplay of materials science, engineering, compliance with standards, and uncompromising quality control measures are crucial in the fabrication of pressure vessels. As technology advances and industries evolve, manufacturers must endure at the forefront of innovation to meet the increasing appeal for safety, efficiency, and acceptable in pressure vessel design and production in Andhra. Ultimately, the cooperative efforts of manufacturers, regulators, and industry stakeholders are crucial in fostering a culture of safety and accuracy in the realm of pressure vessel Manufacturers India.

Contact Us